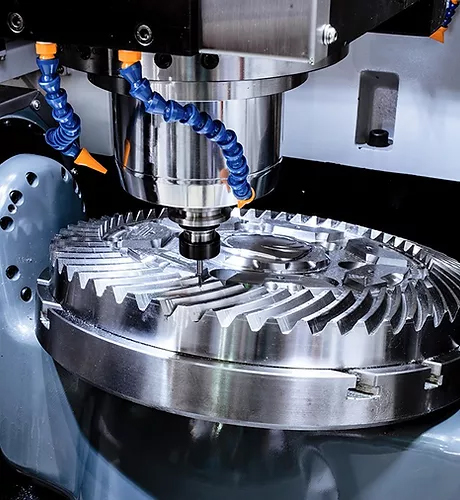

CNC MACHINE SERVICING

Prolong the Life of Your CNC Machine with Maintenance

At Fusion CNC, we know CNC machines are the backbone of modern manufacturing. Our expert maintenance services keep your equipment running smoothly, maximising uptime and productivity.

Whether you operate a single machine or an entire machine shop, Fusion CNC offers comprehensive machine tool maintenance and servicing solutions designed to optimise your equipment's performance and reliability. Our technicians are equipped to service all makes and models of machines and offer service plans that are tailored to your needs. Our CNC machine servicing aims to avoid breakdowns and improve the efficiency of your operations. Our servicing and diagnostics on your machinery offer turnkey solutions so you can get back to production as soon as possible.

Our comprehensive servicing methods include:

- Backlash Set and Alignments Checks

- Change of Batteries

- Oil Replacements and Filter Cleans

- Oil channels cleaned out

- Fans cleaned

- Spindle and encoder belts tensioned

- Lubrication units checked

- Spindle bay cleaned out and all swarf removed

The Significance of Routine CNC Machine Servicing

Consistent maintenance is key to keeping CNC machines running smoothly and dependably. Failing to perform regular upkeep can lead to expensive repairs, lower productivity, and potential safety risks.

By carrying out routine maintenance, you extend the lifespan of your CNC machines and minimise the risk of unexpected malfunctions or downtime. This helps sustain higher production levels, meet project deadlines, and maintain customer satisfaction. Regular care also ensures that your machines remain precise, reducing mistakes and minimising material waste.

Additionally, keeping the safety features and systems of your CNC machines in good condition is essential to safeguarding both the operators and the equipment. Although CNC machine servicing has its costs, they are far lower than the expenses that come with emergency repairs or part replacements.

Frequently Asked Questions on CNC Machine Servicing

The maintenance schedule for CNC machines depends on their usage. For most machines, maintenance is recommended every 12 months. Machines that operate under heavy use may need more frequent inspections.

Warning signs include strange noises, reduced accuracy, poor surface finishes, and faster-than-usual tool wear. Monitoring your machine for these symptoms is essential to prevent bigger issues.

Safety is critical during maintenance work. Always ensure the machine is completely powered off and locked out, follow all safety protocols, and wear the correct personal protective equipment (PPE).

Regular maintenance keeps your machine running smoothly, reduces downtime, and minimises operational errors, which helps boost overall production efficiency and lowers operating costs.

Contact Fusion CNC Today for CNC Machine Servicing

Get in touch with Fusion CNC today for all your CNC repair and servicing needs. Speak with a highly trained and experienced CNC technician today by calling 07955570555.